GM Fabrication Orbital Welding Services

GM Fabrication are experts in every type of welding, and provide a range of orbital welding systems for all types of industries including.

- Food and Beverage

- Pharmaceutical and Medical

- Water Industries

- RO Water

- Aerospace

- Semiconductor

Orbital Welding Advantages

- Increased performance

- Lower overall costs

- Consistently repeatable weld

- Full penetration, uniform welds with little discolouration from oxidation

- Eliminate porosity, cracking and defects

- Small heat-affected zone

- Precise and accurate

- Electronic weld documentation

GM Orbital Welding Capabilities

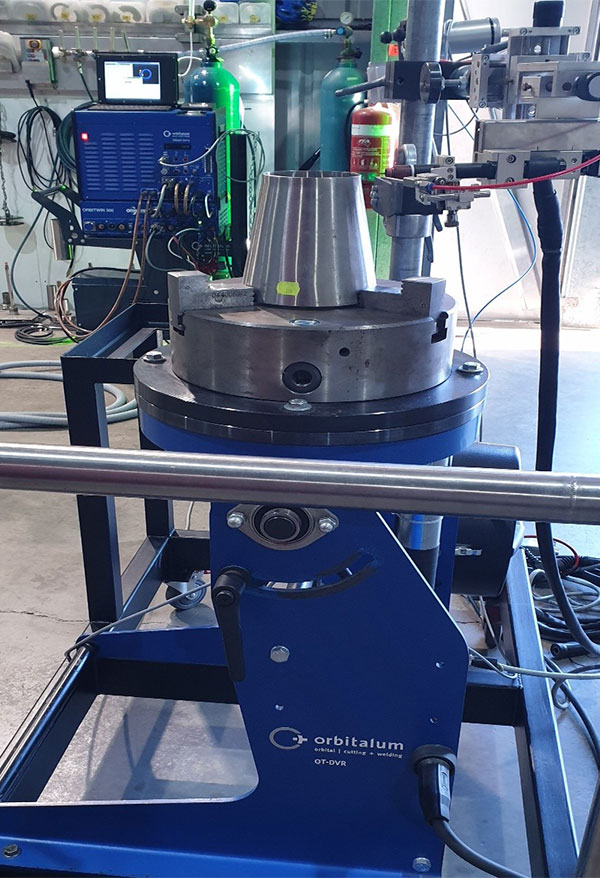

GM Fabrication’s orbital welders are Orbitalum, German designed and manufactured. GM Fabrication’s team are fully trained in pipe work installation, orbital welding process so you can be assured of the highest quality results.

- Orbitalum Orbital DVR 100 Avc / OSG Turn Table Welding System

- DVR 100 Cold wire feed unit

- Orbitalum 300 CA AVC/OSG Power unit

- Orbitalum Orbitwin 300 Parallel switching unit that allows the operation of two weld heads

- OW 170 Orbiweld closed head

- OW 115 Orbiweld closed head

- OW 76 Orbiweld closed head

- Capability of welding 12mm to 152.4mm stainless steel tube

Why Choose Orbital Welding Technology?

This technology is designed for applications where exceptionally high standards in Gas Metal Arc Welding (GMAW) and Tungsten Gas Arc Welding (TGAW) processes are required. It offers a more reliable, higher-quality approach as the process is fully automated.

The welder inputs basic parameters - diameter, material and wall thickness, and the machine generates the welding parameters, resulting in exact controls.

Increased performance, lower overall costs, consistent welds and precise controls.

During the process, the workpiece is kept static while the arc is mechanically rotated around it in continuous motion.

The Orbital Welding equipment is completely computer-controlled and requires only minor assistance from an operator.

As the process is handled mechanically, it allows for a more consistent, reliable weld in comparison to manual welders.

For projects requiring a more consistent, higher weld quality, this is the perfect solution.

Why Choose GM Fabrication?

Many variables can impact weld quality, and it takes experience to ensure the right controls are in place. GM Fabrication ensures that all of these criteria are met, so you can be assured of the highest quality results.

Our orbital welders follow a precise welding method and trained to work to ASME and Australian standards.

What Can You Expect From GM Fabrication?

Perfect Weld, Uniform Weld

Benefit from precision control, unsurpassed by even the most skilled individual welders.

As the process is computerised and controlled, the same weld can be completed repetitively, resulting in less inconsistency and defects between welds.

This delivers a high level of welding accuracy unachievable from the manual welding process.

Cleanliness

The process typically takes place in a cleanroom setting, where components can be welded in a high-purity environment free from contaminants.

This is essential when working with metal tubing as any impurities can cause the entire process to be ruined, costing you precious time and money.

Productivity & Efficiency

Since the process is fully automatic, it's perfect for producing hundreds of welds because of its repeatability.

Due to the process being computer-controlled, labour requirements decrease so it can actually save you money.

Additionally, speed is increased and the welding process can be scheduled well in advance.

Trusted Partners To The Following Companies

All Right Reserved - GM Fabrication LtdWebsite by Digital Stream